Tube Filling Machine

Semi-Automatic Tube Filling, Sealing and Coding Machine

Brand:

Others

Price ₹

80,00,000.00

| General Details: | |

| Model | Semi-Automatic Tube Filling, Sealing and Coding Machine |

| Material | Stainless Steel |

| Machine Type | Semi Automatic |

| Others: | |

| Application | Tube Filling |

| Country of Origin | Made in India |

| Driven Type | Electric |

| Filling Material | Cream |

| Recommended Order Quantity | 1 |

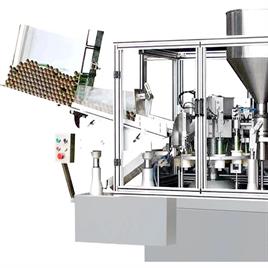

Automatic Tube Filling, Sealing and Coding Machine

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Automatic Tube Filling, Sealing and Coding Machine |

| Others: | |

| Application | Tube Filling |

| Filling Accuracy | +- 1% of Filling Volume |

| Filling Capacity | 10gms to 250gms Aluminum / LAMI / PVC Tubes (With the help of required change parts |

| Output Speed | 20 to 150 Tubes/Minute (Depending on viscosity of material |

| Power Supply | Three Phase / 440 V AC / 50 Hz |

Semi Automatic Timer Filling Machine - Table-Top

Brand:

Others

Price ₹

1,70,000.00

| General Details: | |

| Machine Type | Automatic |

| Material | Stainless Steel |

| Others: | |

| All the functions are PLC controlled. | Very High fill Accuracy of ± 1 %. |

| Availability | In Stock |

| Brand | HMPL |

| Country of Origin | Made in India |

| Digitally controlled settings. | Single phase low voltage requirement. |

| Easy to adjust for different filling volume. | Machine has electronic components such as AC Drive, HMI, PLC and Sensor etc in place of mechanical parts such as Piston, Syringe, Teflon piston rod and pneumatic etc. |

| Filling Capacity | 10 ml Onwards |

| Model Number | HMPL-STF-TT 1 |

| Net Weight | 25 Kg |

| No change parts required for different filling volumes / bottles. | Flow of liquid can be controlled by PLC. |

| Output | For 100 ml 10 to 15 bottles (Water)/Minute |

| Power Consumption | Single Phase / 230V AC / 50Hz (stabilized) |

| Suitable For | 50 ml to 5000 ml |

| The contact parts are made of SS 316L such as Pump, Nozzle etc. | Rigid vibration free construction for trouble free performance. |

| The unit is made compact & versatile as per GMP norms. | The whole structure is made of SS 304 matt finish. |

| Unique Bottle & Nozzle holding device. | Unique feature of "PRIME" is useful to remove air which is inside the filling line very quickly to minimize production loss. Also this prime feature is useful to clean filling line before and after pr |

| Usage/Application | Industrial |

| Use of pharma grade / food grade silicon tube for the flow of liquid to facilitate high temperature liquid (up to 80°C). | Specialized transparent non return valve to avoid dropping. |

| User friendly and high scalability. | No Bottle No Filling |

| Working Height | Table Top Model |

Semi Automatic Timer Filling Machine

Brand:

Others

Price ₹

1,70,000.00

| General Details: | |

| Machine Type | Automatic |

| Material | Stainless Steel |

| Others: | |

| All the functions are PLC controlled. | Very High fill Accuracy of ± 1 %. |

| Availability | In Stock |

| Brand | HMPL |

| Country of Origin | Made in India |

| Digitally controlled settings. | Single phase low voltage requirement. |

| Driven Type | Electric |

| Easy to adjust for different filling volume. | Machine has electronic components such as AC Drive, HMI, PLC and Sensor etc in place of mechanical parts such as Piston, Syringe, Teflon piston rod and pneumatic etc. |

| Filling Capacity | 50 ml onwards |

| Model Number | HMPL-STF-TT 2 |

| Net Weight | 75 Kg |

| No change parts required for different filling volumes / bottles. | Flow of liquid can be controlled by PLC. |

| Output | For 500 ml 10 to 15 bottles (Water)/Minute |

| Power Consumption | Single Phase / 230V AC / 50Hz (stabilized) |

| Suitable For | 50 ml to 5000 ml |

| The contact parts are made of SS 316L such as Pump, Nozzle etc. | Rigid vibration free construction for trouble free performance. |

| The unit is made compact & versatile as per GMP norms. | The whole structure is made of SS 304 matt finish. |

| Unique Bottle & Nozzle holding device. | Unique feature of "PRIME" is useful to remove air which is inside the filling line very quickly to minimize production loss. Also this prime feature is useful to clean filling line before and after pr |

| Usage/Application | Industrial |

| Use of pharma grade / food grade silicon tube for the flow of liquid to facilitate high temperature liquid (up to 80°C). | Specialized transparent non return valve to avoid dropping. |

| User friendly and high scalability. | No Bottle No Filling |

| Working Height | Table Top Model |

if you are interested, please fill the below details: