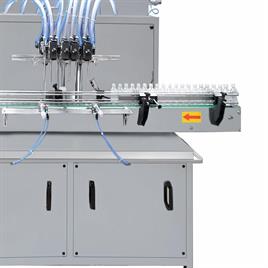

Servo Liquid Filling Machine

Automatic Servo Liquid Filling Machine.

Brand:

Others

Price ₹

12,50,000.00

| General Details: | |

| Voltage | Three Phase + Neutral + Earthing / 415 V AC / 50 Hz |

| Driven Type | Electric |

| Power | Three Phase + Neutral + Earthing / 415 V AC / 50 Hz |

| Others: | |

| Body Material | SS304 |

| Bottle Size | 50 ml to 2000 ml PET/HDPE Bottles/Jars |

| Country of Origin | Made in India |

| Direction of Movement | Left to Right |

| Fill Size | 50 ml to 2000 ml PET/HDPE Bottles/Jars |

| Liquid Filling Accuracy | +- 1 % |

| Liquid Filling Volume | 50 ml to 2000 ml PET/HDPE Bottles/Jars |

| Recommended Order Quantity | 1 |

| Nozzle Type | SS316L |

| Output Speed | 20 to 120 Bottles / Minute (Speed depends upon fill volume |

| Product MOC | GLASS/PET/HDPE Bottles/Jars |

| Warranty | 1 year |

| Weight | 415 KG Approx. |

| Working Height | 875 +- 50 mm Adjustable |

Automatic Servo Liquid Filling Machine

Brand:

Others

Price ₹

7,50,000.00

| General Details: | |

| Model | HMPL |

| Voltage | Three Phase + Neutral + Earthing / 415 V AC / 50 Hz |

| Driven Type | Electric |

| Others: | |

| Warranty | 1 year |

| Weight | 415 KG Approx. |

| Working Height | 875 +- 50 mm Adjustable |

| Business Type | Manufacturer, Supplier |

| Body Material | SS304 |

| Bottle Size | 50 ml to 2000 ml PET/HDPE Bottles/Jars |

| Country of Origin | Made in India |

| Direction of Movement | Left to Right |

| Fill Size | 50 ml to 2000 ml PET/HDPE Bottles/Jars |

| Liquid Filling Accuracy | +- 1 % |

| Liquid Filling Volume | 50 ml to 2000 ml PET/HDPE Bottles/Jars |

| Nozzle Type | SS316L |

| Output Speed | 20 to 120 Bottles / Minute (Speed depends upon fill volume |

| Product MOC | GLASS/PET/HDPE Bottles/Jars |

Automatic Servo Liquid Filling Machine

Brand:

Others

Price ₹

12,39,000.00

| General Details: | |

| Material | Stainless Steel |

| Driven Type | Electric |

| Power | 3 phase |

| Usage/Application | SERVO FILLING MACHINE |

| Voltage | 440 V AC |

| Model | hmpl–pre–rbf |

| Others: | |

| working height | 850 ± 50 mm adjustable |

| Weight | 400 |

| Warranty | 1 year |

| product moc | pet/hdpe bottles/jars |

| power supply | three phase + neutral + earthing / 440 v ac / 50 hz |

| power consumption | 2. 5 kva |

| output speed | 20 to 80 bottles/minute(speed depends upon fill volume & viscosity of liquid) |

| Number Of Phases | Three Phase |

| net weight | 400 kg approx. |

| Model Name/Number | HMPL-PRE-RBF |

| Frequency | 50 Hz |

| filling volume | 50 ml to 5000 ml pet/hdpe bottles/jars |

| Filling Speed | 100 BPM |

| filling head | 4/6/8 heads |

| Filling Head | 4, 6, 8 |

| direction of movement | left to right |

| dimensions | 2100 mm (l) x 900 mm (w) x 2000 mm (h) approx. |

| Brand | HMPL |

| Availability | In Stock |

| air supply | 4 to 6 kg/cm² |

| Air Pressure | 4 TO 6 KG |

if you are interested, please fill the below details: