Pre Filled Syringe Filling Machine

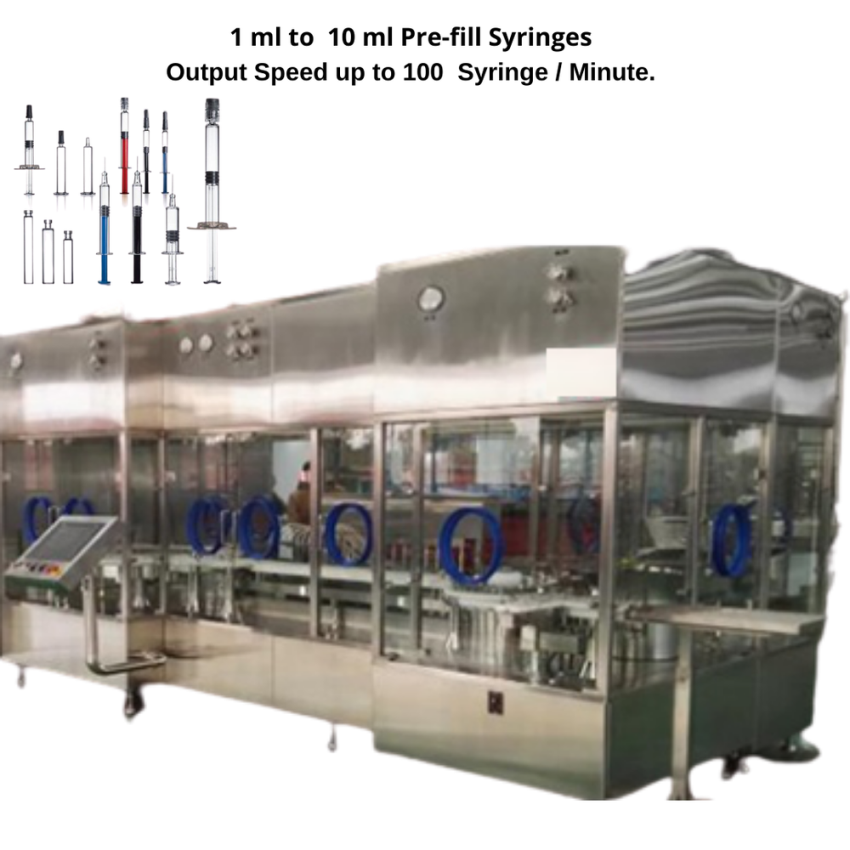

Pre-Filled Syringe Filling & Stoppering Machine

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Power | 2–4 kW |

| Voltage | 230 - 440 V |

| Frequency | 50 Hz |

| Usage/Application | Filling and stoppering of glass/plastic pre-filled syringes in pharmaceuticals |

| Others: | |

| Brand Name | Harikrushna Machines |

| Business Type | Manufacturer, Supplier |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 Piece |

| Automatic Grade | Semi Automatic |

| Condition | New |

Automatic Pre-Filled Syringe Plunger Rod Insertion and Labelling Machine

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Modal | Automatic Pre-Filled Syringe Plunger Rod Insertion and Labelling Machine |

| Others: | |

| Country of Origin | Made in India |

| Dosing accuracy | +- 1% |

| Filling Capacity | 0.5 ml onwards |

| Filling station | 1 No. |

| Output / minute | Up to 100 PFS per minute @ 1 ml (Output may vary based on nature of the filling subs |

| Power Supply | Three Phase |

| Suitable for | Aqueous substance / Viscous substance with the help of change parts. |

| Working height | 850 mm +- 50 mm |

Pre-Filled Syringe Packaging Line

Brand:

Others

Price ₹

1,50,00,000.00

| General Details: | |

| Power | 3–7 kW |

| Voltage | 230 - 440 V |

| Frequency | 50 Hz |

| Phase | 3 Phase |

| Usage/Application | For Packaging Pre-filled Syringes and Dental Cartridges |

| Others: | |

| Min. Order Quantity | One |

| Brand Name | Harikrushna Machines |

| Condition | New |

| Automatic Grade | Automatic |

| Type | Automatic Packaging Line |

| Country of Origin | India |

| Business Type | Manufacturer, Supplier |

Pre Filled Syringe Labeling Machine

Brand:

Others

Price ₹

7,51,000.00

| Others: | |

| Availability | In Stock |

| Country of Origin | Made in India |

| Dosing accuracy | 1 |

| Filling Capacity | 0.5 ml onwards |

| Filling station | 1 No., 2 No., 5 No. & 10 Nos. |

| Output / minute | Up to 100 PFS per minute @ 1 ml (Output may vary based on nature of the filling substance and volume |

| Suitable for | substance |

Pharmaceutical Machines

Brand:

Others

Price ₹

8,50,000.00

| Others: | |

| Availability | In Stock |

| Country of Origin | Made in India |

| Dosing accuracy | 1 |

| Filling Capacity | 0.5 ml onwards |

| Filling station | 1 No., 2 No., 5 No. & 10 Nos. |

| Output / minute | Up to 100 PFS per minute @ 1 ml (Output may vary based on nature of the filling substance and volume |

| Suitable for | Aqueous substance / Viscous substance with the help of change parts. |

Pre Filled Syringe Filling Machine

Brand:

Others

Price ₹

18,00,000.00

| Others: | |

| Availability | In Stock |

| Country of Origin | Made in India |

| Dosing accuracy | +- 1% |

| Filling Capacity | 0.5 ml onwards |

| Filling station | 1 No., 2 No., 5 No. & 10 Nos. |

| Output / minute | Up to 100 PFS per minute @ 1 ml (Output may vary based on nature of the filling substance and volume |

| Power Supply | Three Phase, 440 V, 50 Hz (Stabilized) |

| Suitable for | Aqueous substance / Viscous substance with the help of change parts. |

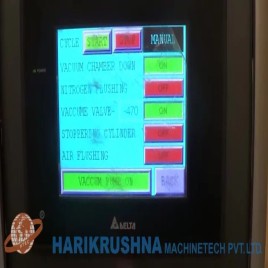

Pre Filled Syringe Filling Machine

Brand:

Others

Price ₹

18,00,000.00

| Others: | |

| Air consumption | 5 CFM |

| Air supply | 6 to 8 Kg |

| Availability | In Stock |

| Country of Origin | Made in India |

| Dosing accuracy | 1 |

| Filling Capacity | 0.5 ml onwards |

| Filling station | 1 No., 2 No., 5 No. & 10 Nos. |

| Nitrogen supply | 5 CFM pressure (Customer scope) |

| Output / minute | Up to 100 PFS per minute |

| Power Supply | Three Phase, 440 V, 50 Hz (Stabilized) |

| Suitable for | Aqueous substance Viscous substance with the help of change parts |

| Working height | 850 mm +- 50 mm |

Pre-Filled Syringe Filling, Stoppering And Labeling Machine, Capacity: 100 PFS

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Capacity | 100 PFS |

| Material | Stainless Steel |

| Usage/Application | Industrial |

| Others: | |

| Automation Grade | Automatic |

| Availability | In Stock |

| Brand | HMPL |

| Country of Origin | Made in India |

| Driven Type | Electric |

| Packaging Type | Syringe Filling, Labeling and Stoppering Machine |

| Power Consumption | Three Phase, 440 V, 50 Hz (Stabilized) |

| Size/Dimension | 850 mm +- 50 mm |

Pre- Fill Syringe Packaging Line

Brand:

Others

Price ₹

45,00,000.00

| General Details: | |

| Material | Stainless Steel |

| Usage/Application | Pharma |

| Others: | |

| Automation Grade | Automatic |

| Availability | In Stock |

| Driven Type | Electric |

| Machine Type | Automatic, Semi-Automatic |

| Packaging Type | 1 No., 2 No., 5 No. & 10 Nos. |

| Power Consumption | Three Phase, 440 V, 50 Hz (Stabilized) |

if you are interested, please fill the below details: