Eye Drop Filling Machine

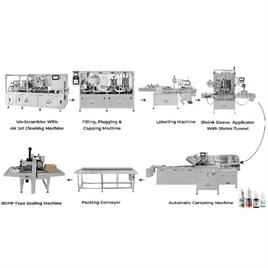

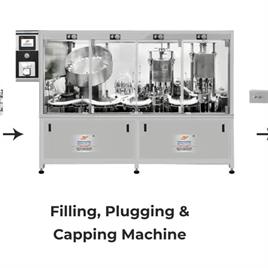

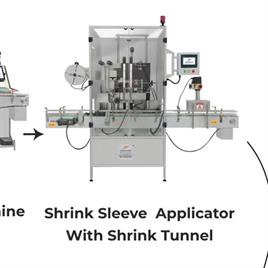

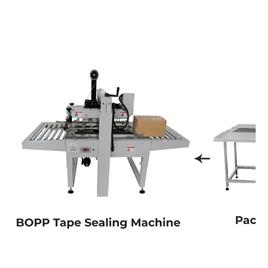

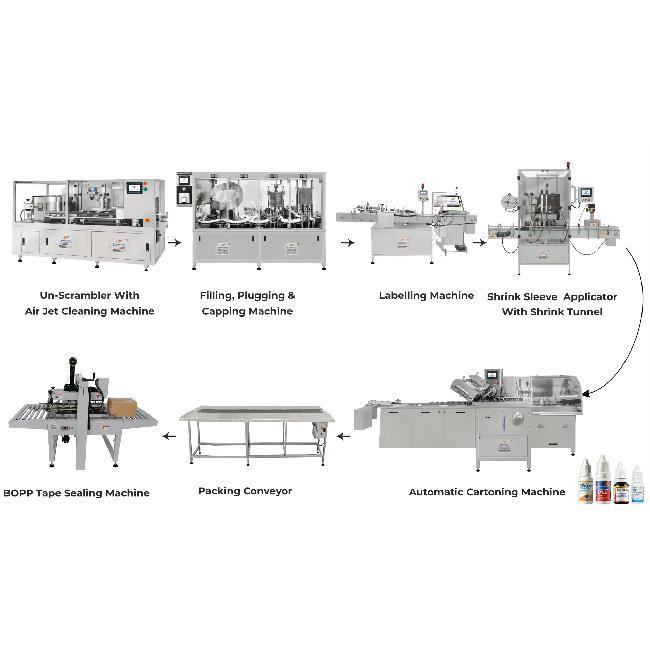

Complete Eye/ Ear Drop Packing Line

Brand:

Others

Price ₹

90,00,000.00

| General Detail: | |

| Modal | Complete Eye/ Ear Drop Packing Line / HMPL |

| Capacity | 200 bottle/min |

| Others: | |

| Bottle Size | 5 ml to 15 ml |

| Country of Origin | Made in India |

| Electric Power | 3 Phase +N +E 440V AC/ 50 Hz |

| Recommended Order Quantity | 1 Unit |

| MOC | SS316L |

| Automatic Grade | Fully Automatic |

| Voltage | 220 - 440V |

| Country of Origin | India |

if you are interested, please fill the below details: