Automatic Sticker Labelling Machine

Round Automatic Single Side High Speed Sticker Labeling Machine, 380 V Ac

Brand:

Others

Price ₹

7,75,000.00

| General Details: | |

| Capacity | 1 ML TO 20 ML |

| Material | Stainless Steel |

| Frequency | 50 Hz |

| Automation Grade | Automatic |

| Model | HMPL–SSVHL |

| Voltage | 380 V AC |

| Others: | |

| Air Supply | 2 to 4 Kg/Cm2 (Incase ofContact Printer) |

| All moving parts of the machine covered by safety guards of SS. | All expose parts of MS are powder coated / hard chrome plated. |

| Availability | In Stock |

| Bottle Type | Round |

| Brand | HMPL |

| Conveying system to convey the product through in-feed screw. | Systemequipped with imported AC frequency variable drive for variable speed with constant torque. |

| Country of Origin | Made in India |

| Dimensions | 915 mm(L) x 915 mm(W) x 850 + 50 mm (H) |

| Emergency stop switch. | Noise level Less than 62 DB. |

| Fiber optic based label gap sensor to sense the gap between two labels (Sensor Make: LEUZE/BANNER/SUNEX) | Most reliable and proven components such as Festo/SMC make pneumatic and electrical/electronic such as Panasonic/Bonfiglioli/Motovario make AC motor, Delta /Allen Bradley make AC Drives, PLC HMI (Touc |

| Label Size | As per your samples |

| Model Name/Number | HMPL-SSVHL |

| Net Weight | 350 kgs Approx. |

| Output Speed | Up to 250 Labels/Minute (Speed depends on label and products size) |

| Phase Type | Three Phase |

| PLC HMI for total operation of the machine with programming facility. | Fiber optic based product sensor to sense the product (Sensor Make: LEUZE-/BANNER/SUNEX). |

| Power Supply | Three Phase / 380V AC / 50Hz |

| Product Samples | Ampoules / Vials (with the help of change parts) |

| Reel mechanism (Size: 305mm) to hang the roll with core ID of 76mm (3"). | Break assembly to avoid variation during releasing of roll. |

| Specially designed drive mechanism for Label Release. | Dispensing unit to dispense labels. |

| The unit is made compact Versatile as per GMP Norms. | Structure made of MS cladding with SS 304. |

| Usage/Application | Sticker Labelling |

| Various label position adjustment with the help of sliding pipe assembly. | Easy change over time is 15 to 20 minutes. |

| Working Height | 850+50mm Adjustable |

| Wrap around mechanism (timing belt) to wrap the label on product. | No product No labeling. |

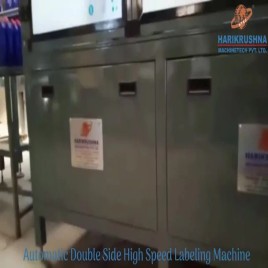

Automatic Double Side Sticker Labeling Machine

Brand:

Others

Price ₹

6,50,000.00

| General Details: | |

| Material | Stainless Steel |

| Frequency | 50 Hz |

| Model | HMPL–DSVL |

| Voltage | 415 V |

| Others: | |

| Air Supply | N.A. |

| All moving parts of the machine covered by safety guards of SS | All expose parts of MS are powder coated / hard chrome plated |

| All moving parts of the machine covered by safety guards of SS | Fiber Optic based Product sensor to sense the product (Sensor Make: LEUZE/BANNER/SUNX) |

| Availability | In Stock |

| Bottle Type | FLAT OVAL SQUARE ROUND ETC |

| Brand | HMPL |

| Controller | Automatic |

| Conveying systemequipped with imported AC frequency variable drive for variable speed with constant torque | Unique in-feed screw to ensure uniform distance between two products |

| Country of Origin | Made in India |

| Delrin slate conveyor | Conveying system to convey the product with easy adjustable side guide |

| Dimensions | 2745 mm(L) x 1400 mm(W) x 1800 mm (H) Aprox. |

| Dispensing Unit to dispense labels | Various label position adjustment with the help of sliding pipe assembly |

| Fiber Optic based Label Gap sensor to sense the gap between two labels (Sensor Make: LEUZE/BANNER/SUNX) | Reel mechanism (Size: 305mm) to hang the roll with core ID of 76 mm (3") |

| Imported AC frequency variable drive for variable speed with constant torque | Specially designed drive mechanism for Label Release |

| Label affixing on the product with the help of nylon brush and sponge roller | No Bottle No Labeling |

| Label release mechanism | Break assembly to avoid variation during releasing of roll |

| Label size | As per your Samples (Specify size by customer) |

| Model Name/Number | HMPL-DSVL |

| Net Weight | 450 Kg Approx. |

| Output speed | Up to 120 Products/Minute (Speed depends on label and products size) |

| Power Supply | Three Phase / 415 V AC / 50Hz |

| Product Samples | Oval /Flat/Square/Round Products |

| The unit is made compact Versatile as per GMP Norms | Structure made of MS cladding with SS 304 |

| Top Conveyor to holding product at the time of labeling | Machine suitable for product like Round / Rectangular / Flat / Oval /Square |

| Usage/Application | Sticker Labeling |

| Working Height | 850 mm ± 50 mm Adjustable |

50 Hz Round Automatic Sticker Labeling Machine, 230 V

Brand:

Others

Price ₹

3,25,000.00

| General Details: | |

| Capacity | 30 PPM |

| Material | Stainless Steel |

| Frequency | 50 Hz |

| Phase | Single Phase |

| Automation Grade | Semi-Automatic |

| Voltage | 230 V |

| Others: | |

| Availability | In Stock |

| Bottle Type | Round |

| Brand | HMPL |

| Controller | stepper or servo |

| Country of Origin | Made in India |

| Model Name/Number | HMPL LAW SSVL |

| Speed | 120 to 200 bpm |

| Type | Labeling Machine |

| Usage/Application | Sticker Labeling |

50 Hz Automatic Sticker Labeling Machine For Round And Flat Bottles, 230 V Ac

Brand:

Others

Price ₹

4,50,000.00

| General Details: | |

| Frequency | 50 Hz |

| Model | HMPL-SSVL-RF |

| Voltage | 230 V AC |

| Others: | |

| 5 feet long Rubberized Endless Conveyor Belt | Conveying system to convey the product with easy adjustable side guide |

| Air Supply | 4 to 6 kg/cm² (If use Contact type Batch Printer) |

| All moving parts of the machine covered by safety guards of SS | All expose parts of MS are powder coated / hard chrome plated |

| Availability | In Stock |

| Bottle size (Ø) | 15mm Ø to 90mm Ø |

| Bottle Type | Round |

| Brand | HMPL |

| Break assembly to avoid variation during releasing of roll | Various label position adjustment with the help of sliding pipe assembly |

| Conveying systemequipped with imported AC frequency variable drive for variable speed with constant torque | Unique motorized separator to ensure uniform distance between two products |

| Country of Origin | Made in India |

| Dimensions | 1525 mm (L)x 950 mm (W)x 1800mm(H) Approx. |

| Dispensing Unit to dispense labels | Reel mechanism (Size: 305mm) to hang the roll with core ID of 76 mm (3") |

| Fibre Optic based Label Gap sensor to sense the gap between two labels (Sensor Make: LEUZE/BANNER/SUNX) | Most reliable and proven components such as Festo/SMC make pneumatic and electrical/electronic such as Panasonic/Bonfiglioli/Motovario make AC motor, Delta /Allen Bradley make AC Drives, PLC HMI, MCB |

| Label size | Min: 15 mm (H) x 35 mm (L) Max: 90mm (H) x 150 mm (L) |

| Machine Suitable for Round flat Product like Vial/ Bottle/ Jar/ Tin / Can and Container | Specially designed drive mechanism for Label Release |

| Model Number | HMPL-SSVL-RF |

| Net Weight | 350 Kg Approx. |

| No Product No Labeling | Fibre Optic based Product sensor to sense the product (Sensor Make: LEUZE-/BANNER/SUNX) |

| Output speed | 120 to 150 Products/Minute (Speed depends on label and products size) |

| Power Consumption | 2.5 KVA |

| Power Supply | SinglePhase + Neutral + Earthing/ 230 V AC/ 50Hz |

| Products | Round/Flat Products |

| Specially designed wrapping unit to wrap label on product | The Wrapping belt is made of specialized nylon sponge material for longer life |

| The unit is made compact Versatile as per GMP Norms | Structure made of MS cladding with SS 304 |

| Unique machine for all round bottles label application without change parts | Full / Partiallabeling is possible |

| Usage/Application | Labeling |

| Working Height | 850 mm ± 50 mm Adjustable |

Round Self-adhesive Labeler Machine, For Sticker Labeling, 230v Ac

Brand:

Others

Price ₹

5,50,000.00

| General Details: | |

| Capacity | 60 to 150 Products/Minute |

| Material | SS Steel |

| Voltage | 230V AC |

| Others: | |

| Availability | In Stock |

| Bottle Type | Round |

| Controller | PLC-HMI |

| Model Name/Number | HMPL-SSVL-RF |

| Production Capacity | Bottles |

| Speed | 60 to 150 Products/Minute |

| Usage/Application | Sticker Labeling |

Round Automatic Horizontal Labeling Machine With Roller Conveyor

Brand:

Others

Price ₹

4,50,000.00

| General Details: | |

| Capacity | 40 TO 60 PPM |

| Material | SS |

| Others: | |

| Availability | In Stock |

| Bottle Type | Round |

| Brand | HMPL |

| Model Name/Number | HMPLBSHL |

| Speed | 40 TO 60 PPM |

| Type | Fully Automatic |

| Usage/Application | Sticker Labeling |

50 Hz Round Automatic Sticker Labeling Machine With Turntable, 230 V Ac

Brand:

Others

Price ₹

7,50,000.00

| General Details: | |

| Frequency | 50 Hz |

| Phase | Three Phase |

| Model | HMPL-SSVL with 24" TURN TABLE |

| Voltage | 230 V AC |

| Others: | |

| Air Supply | 4 to 6 kg/cm² (If use Contact type Batch Printer) |

| All moving parts of the machine covered by safety guards of SS 304 | All exposed parts of MS are either powder coated or hard chrome plated |

| Availability | In Stock |

| Bottle Range | Round Products |

| Bottle size (Ø) | 15mm Ø to 90mm Ø |

| Bottle Type | Round |

| Brand | HMPL |

| Country of Origin | Made in India |

| Dimensions | 1525 mm (L)x 950 mm (W)x 1800mm(H) Approx. |

| Label size | Min: 15 mm (H) x 35 mm (L) Max: 90mm (H) x 150 mm (L) |

| Machine Suitable for Round Product like vial / Bottle/ Jars/ Tin and container | Synchronized turn table and Conveying system equipped with AC frequency variable drive for variable speed and constant torque |

| Model Number | HMPL-SSVL with 24 Inch Turn Table |

| Most reliable and proven components such as pneumatics Festo-Germany/SMC-Japan/ make | Most reliable electrical / electronic such as Bonfiglioli/Motavario/PanasonicAC motor, Delta/Allen Bradley - UK make Drives, PLC with feather touch HMI, MCBs, relay-CE make |

| Net Weight | 350 Kg Approx. |

| No Product No Label | Break assembly to avoid variation during releasing of roll |

| Output speed | 120 to 150 Products/Minute (Speed depends on label and products size) |

| Power Consumption | 2.5 KVA |

| Power Supply | ThreePhase + Neutral + Earthing/ 230 V AC/ 50Hz |

| Reel mechanism (Size(OD): 305mm) to hang the roll with core ID of 76mm (3") | Specially designed driveLabel Release Mechanism |

| Rubberized Endless Conveyor Belt | Specially designed Machine with inbuilt Turn Table suitable for Online and offline application |

| Specially designed synchronized wrapping unit with wrapping belt to wrap label on the bottle | Dispensing Unit to dispense labels |

| Speed | 200 BPM |

| The unit is made compact Versatile as per GMP Norms | The Structure is made of MS cladding with SS 304 |

| Usage/Application | Sticker Labeling |

| Various label position adjustment with the help of sliding pipe assembly | Fiber Optic based Product sensor to sense the product (SENSOR MAKE: LEUZE/BANNER/SUNEX) |

| Working Height | 850 mm ± 50 mm Adjustable |

60 Hz Round Automatic Horizontal Sticker Labeling Machine, 110 V Ac

Brand:

Others

Price ₹

7,50,000.00

| General Details: | |

| Frequency | 60 Hz |

| Phase | Single Phase |

| Model | HMPL–BSHL |

| Voltage | 110 V AC |

| Others: | |

| 5 Feet long rubberized endless conveyor belt. | Conveying system to convey the product with easy adjustable side guide. |

| Air Supply | 2 to 4 Kg/Cm2 (In case of Contact Printer) |

| All moving parts of the machine covered by safety guards of SS. | All expose parts of MS are powder coated / hard chrome plated. |

| Availability | In Stock |

| Bottle Type | Round |

| Brand | HMPL |

| Break assembly to avoid variation during releasing of roll. | Various label position adjustment with the help of sliding pipe assembly. |

| Conveying systemequipped with imported AC frequency variable drive for variable speed with constant torque. | Specially designed drive mechanism for Label Release. |

| Dimensions | 2745 mm(L) x 490 mm(W) x 850 + 50 mm (H) |

| Dispensing Unit to dispense labels. | Reel mechanism (Size: 305mm) to hang the roll with core ID of 76 mm (3"). |

| Fiber Optic based Product sensor to sense the product (Sensor Make: LEUZE/BANNER/SUNX). | Fiber Optic based Label Gap sensor to sense the gap between two labels (Sensor Make: LEUZE/BANNER/SUNX). |

| Label affix with nylon brush or sponge roller. | No Product No Labeling. |

| Label Size | Min: 15mm Width Max: 90 mm Width |

| Model Name/Number | HMPLBSHL |

| Model Number | HMPL-BSHL |

| Net Weight | 250 kgs Approx. |

| Output Speed | Up to 250 Labels/Minute (Speed depends on label and products size) |

| Power Supply | Single Phase / 110 Volts AC / 60Hz |

| Product Samples | Cartons/Pouches/Bottles etc. |

| Speed | 120 PPM OR MORE |

| The unit is made compact Versatile as per GMP Norms. | Structure made of MS cladding with SS 304. |

| Usage/Application | Labeling |

| Working Height | 850+50mm Adjustable |

Automatic Round Bottle Sticker Labeling Machine With Pneumatic Wrapping

Brand:

Others

Price ₹

4,45,500.00

| General Details: | |

| Material | Stainless Steel |

| Automation Grade | Automatic |

| Voltage | 230 V AC |

| Others: | |

| Availability | In Stock |

| Bottle Type | Round |

| Brand | HMPL |

| Conveyor Type | Rubberized Conveyor |

| Country of Origin | Made in India |

| Phase Type | Single Phase |

| Usage/Application | Labeling On Round Bottle |

50 Hz Round Automatic Single Side Sticker Labeling Machine, 230v Ac

Brand:

Others

Price ₹

4,50,000.00

| General Details: | |

| Capacity | Up to 120 Bottles/Minute |

| Material | SS STEEL |

| Frequency | 50 Hz |

| Voltage | 230V AC |

| Others: | |

| Availability | In Stock |

| Bottle Type | Round |

| Controller | PLC & HMI |

| Model Name/Number | HMPL-SSVL |

| Production Capacity | 10 |

| Speed | Up to 120 Bottles/Minute |

| Usage/Application | Sticker Labeling |

50 Hz Round Automatic Bottle Sticker Labeling Machine, 440 V Ac

Brand:

Others

Price ₹

4,75,000.00

| General Details: | |

| Frequency | 50 Hz |

| Phase | Three Phase |

| Model | HMPL–PRE–RBL |

| Voltage | 440 V AC |

| Others: | |

| Air Supply | 4 to 6 Kg/cm² (If use Contact type Coder) |

| Availability | In Stock |

| Bottle Range | Vials/Bottles |

| Bottle Size (Ø) | 15mm Ø to 90mm Ø |

| Bottle Type | Round |

| Brand | HMPL |

| Consists of specially designed brake assembly to avoid variation during process of labelling. | The wrapping belt is made of specialized nylo – sponge material for longer life. |

| Conveyor made of specialized noiseless Nylo-grip endless rubberized belt for longer life durability. | Dispenser consists of genuine imported fiber optic based product sensors label gap sensors. |

| Country of Origin | Made in India |

| Dimensions | 2100mm (L)x 1100mm (W)x 1800mm(H) Approx. |

| Label Size | Min: 15 mm (H) x 35 mm (L), Max: 90mm (H) x 150 mm (L) |

| Model Name/Number | HMPL-PRE-RBL |

| Net Weight | 350kgs Approx. |

| No Product - No Label. | Covered with acrylic doors. |

| Output Speed | Min: 15 mm (H) x 35 mm (L), Max: 90mm (H) x 150 mm (L) |

| Power Consumption | 2.5 KVA |

| Power Supply | 3 Phase + Neutral + Earthing/ 440V AC/ 50Hz |

| Printing facility (Inkjet Thermal–Non contact type Hot Foil, Cassette Coder– contact type) can be provided (OPTIONAL). | Unique Single Window Rejection system (OPTIONAL). The product gets rejected in case when the label is not applied, quality of printing is not accurate; quality of bar code/pharma code is not accurate. |

| The contact parts are made of SS304. | Rigid vibration free construction for trouble free performance. |

| The machine can be set for 10 different programs as per the product size. | The individual parameter such as p-time, Delay time, p-length speed can be set on the PLC the same can be seen in the "Current" program mode. |

| The unit is made compact versatile as per GMP norms. | The structure is made of MS cladded with SS304. |

| To have easy understanding of the daily production ratio, production counter is given with the password protection. This will give the clear picture / figure about the batch production. | On the RUN mode screen, speed of label dispensing motor, set speed of machine, actual speed of machine number of labelled products can be seen. |

| Usage/Application | Sticker Labeling |

| User friendly since it is easy to operate through PLC. | Very less maintenance required on account of less usage of mechanical components such as gears, chain, sprockets. V-belt, pulleys etc. |

| Working Height | 850 mm ± 50 mm Adjustable |

50 Hz Round Automatic Sticker Labeling Machine Low SSVL, 230 V Ac

Brand:

Others

Price ₹

2,80,000.00

| General Details: | |

| Material | Stainless Steel |

| Frequency | 50 Hz |

| Phase | Single Phase |

| Automation Grade | Automatic |

| Voltage | 230 V AC |

| Others: | |

| Availability | In Stock |

| Bottle Type | Round |

| Brand | HMPL |

| Country of Origin | Made in India |

| Model Name/Number | LOW SSVL |

| Usage/Application | Labeling |

50 Hz Round Automatic Sticker Labeling Machine, 230 V

Brand:

Others

Price ₹

5,50,000.00

| General Details: | |

| Capacity | 120 BPM |

| Material | Stainless Steel |

| Frequency | 50 Hz |

| Phase | SINGLE Phase |

| Automation Grade | Automatic |

| Voltage | 230 V |

| Others: | |

| Availability | In Stock |

| Bottle Type | Round |

| Brand | HMPL |

| Model Name/Number | SSVL |

| Speed | 120 BPM |

| Type | Labeling Machine |

| Usage/Application | Sticker Labeling |

if you are interested, please fill the below details: